The features of AOLANG automatic steel rule bending machine

We are continuously improving and upgrading our steel rule bender through feedback from our huge amount of machine user in the market.

- User friendly controlling software of the machine

- Modularization design,easy to replace wearing parts

- Structure minimalist design,less sensors, less failure possibility

If you are still a die shop using manual bending tools, auto steel rule bending machine can bring you what?

1. It can bring you 10 times the productivity increase so as to get more orders to earn more money. Because the automatic rule bender is controlled by computer. It can work continuously, significantly improve the production efficiency of die-making.

2.Auto steel rule bender if work with laser die cutting machine can significantly improve the accuracy and consistency of the dies you make. It means that the wood dies quality from your die shop is higher than that of your competitors.

3.Steel rule bender can help you save labor cost. The traditional manual die-making requires a lot of labor, resulting in increased die costs and lower profits. Moreover, making dies by hand may mistake happens and cause material waste.

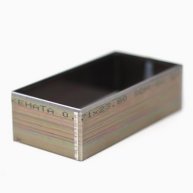

AOLANG 32CN PRO BENDER

The 32CN PRO is our highest-class automatic steel rule bending machine with a wide range of features including standard bending, bridging, lipping, and cutting. Additional advanced features include nicking, broaching, seamless joints and more.

- Servo motor driving system

- Dual screw rod blade feeding

- All function part modular design

- 3 sets of broaching angle

Choose your automatic rule bending machine according to the type of dies you make (3)

What is steel rule height? (3)

What industry should buy an automatic bending machine?

- Steel rules bending samples

AOLANG LASER automatic steel rule bending machine mian features:

Multifunctionality: Automatic bending machine not only has fast bending, cutting, bridgeing, lipping four basic functions, but also can be equipped with advanced functions such as nicking and broaching.

Automatic control: The machine is controlled through the computer, support AutoCAD, AI and other software. And working format can be dxf,AI and DWG, etc. And the drawings can be imported with one key, then the machine work automaticly. No need your machine operator to stand by all the time,just waiting for the machine complete the bending jobs automaticly.

Superior configuration: Our machine adopter the most stable Japanese motor and pneumatic components to ensure that steel rule bender life expectancy of more than 6 years. The wear parts(bending,bridging,cutting tools) use high strength and hardness mould steel to prolong the service life and save the replacement cost.

The auto bending machine is controlled by computer, the software interface is very user-friendly, easy to learn, and the machine’s degree of automation is very high. Only need to manually import the dies drawing, and then it can automatically feed, automatically bending, cutting etc., When it is running then almost no need any human intervention.

The price of an automatic bender depends on what functions you need.

If you are just starting to make cutting dies, our AL-910C entry level model can match your work. It’s price is competitive.

Models AL-32 and AL-32 PRO have more advanced functions and are more expensive.

More details,please contact our sales team for technical specifications and an official quotation.

The machine’s power consumption is 5KW and need to connect to 0.8mpa air compressor.

Steel rule bender actually no special maintenance, just the following two routine maintenance.

1. Clean the exterior and interior parts of the steel rule bender from iron filings and dust daily.

2. Grease or lubricate the mechanical transmission parts(screw rod and cutting,bending molds), recommended once every 3 months.

This depends on the laser power of your laser die cutting machine,in our experience

- 1 set of 400W-600W LASER die cutter matches 1 set automatic steel rule bender

- 1 set of 1500W-2000W laser die cutter matches 2-3 sets of steel rule bender

- We can send engineers from our head office to provide installation and training services, as well as provide some guidance on the how to making dies.

- In some countries we can provide installation and training services through our machine dealers.