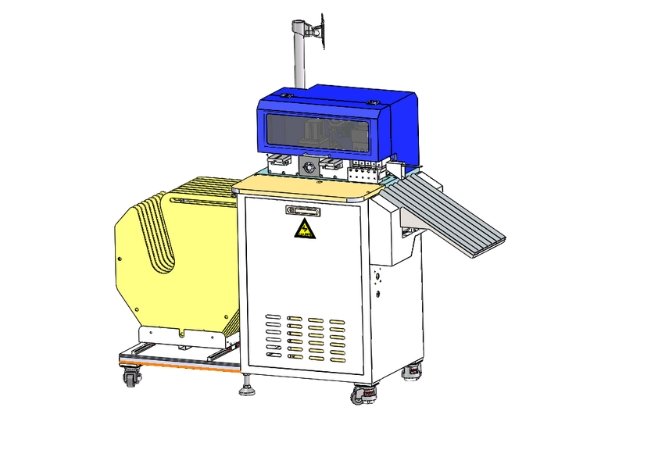

AL-10H PRO Advanced Creasing Cutting Machine

In fact, it is a multi-purpose machine that can not only form creasing lines, but also form normal steel rules, and can be equipped with the optional perforation function.

- Horizontal working station design, the blade enters the machine horizontally.

- Customizable module design,you can just tell us what features you need?

- Highly adaptable design, 1pt 2pt 3pt thickness creasing rules all can be cut.

- Compact design with small footprint and low power consumption.

Visual Modular Design

The AL-10H PRO has a simple structural design. All work stations are visualized and modules can be adjusted and replaced at any time. The bridge forming stations can be manually adjusted to any height you want.The width of the bridge can be set to any width you want through the system parameters.

The key parts of the machine are recognized by sensors, which guarantees that the wrong part can be read in case of error happens in any part of the machine. Then you can find the parts and replace the parts easily .

Coil Creasing Rule and Steel Rule Storage

The 8 layers of coil placement space is the biggest difference between it and our regular AL-10H standard creasing cutting machine. You can place up to 8 coils different thicknesses or heights of creasing rule. Whereas the standard version of the machine can only place up to 2 coils. This more layers space allows you to not have to change different rules so often, wasting time changing them.

The design allows the knives entry horizontally into the machine. This is more conducive to the physical stresses on the punching molds, making the machine more efficient and the molds not easily worn out.

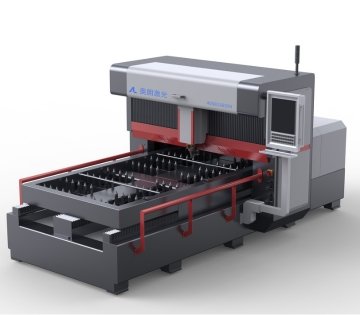

The Machine Function to Make Teeth Rules

We have found that there are many die-makers who need to buy and use teeth steel rule. However, if you buy ready-made teeth steel rules directly from the market. On the one hand, the price is much higher than normal steel rule. On the other hand, there are not many choices for the pitch of the teeth.

If you buy our horizontal creasing cutting machine, you can customize your own creasing cutter at any time. And the height and width of the teeth can be customized according to your needs.

- Data sheet

| Horizontal Creasing Cutting Machine | |

| Machine Model | AL-10H PRO |

| Crease (thickness) | 0.45-0.71-1.05mm(1pt 2pt 3pt) |

| Crease(height) | 20-32mm(common size like 22.3,23.0,23.8mm) |

| Minimum cutting size on front/back | 1-1.5 mm depends on the blade thickness |

| Standard functions | Crease Cutting,bridging,lipping,Perforating |

| Blade feeding accuracy | ±0.02mm |

| Crease standard for lipping | 2.6-23.8mm/0.45-0.71(1pt 2pt) |

| The way of cut and bridging | Punched by molds(tool) |

| Gas supported | 0.6-0.8Mpa compressor air |

| Voltage and Frequency | AC 380V 50Hz 3P |

| Gross Power | 1.5 KW |

| Machine Size and Weight | 150CM*75CM*165CM 240KG |

| The best graphics formats | dxf.ai.dwg format |

More than just a creasing cutting machine

Yes, the main function of this machine is creasing line cutting. But it is not limited to this, it can also help a die-maker to do other jobs like waste removal dies rules,teeth shape rules. It is a very good and comprehensive help.

1. It can be adapted to different types of materials. This not limited to creasing rules, but also to steel rule bender. If you use a lot of steel rule in straight shape, you can buy this machine. Its working speed is 2-3 times faster than automatic steel rule bender.

2. It is feature rich and can be customized. You can not only customize the waste removal steel rules processing station, but also the teeth shape steel rule forming station. This will great help you to make different types of cutting dies.

Yes,everything you can see in the machine pictures will included as standard.

- Prepare the power supply : 220V single phase,and total power will be 1500W

- Please prepare 0.6-0.8Mpa air compressor to support the machine work.

Whole machine with 1 year warranty. Any parts shut down,we will replace new one for you.

And local service is available.

- Engineer travelling to all over the world for installation and can speak English well

- Also can get the service from our machine agent. Already have service in more than 10 countries.