Waterjet Cutting Machine for Ejection Rubber in the Die-Making Industry Model: AL-1106

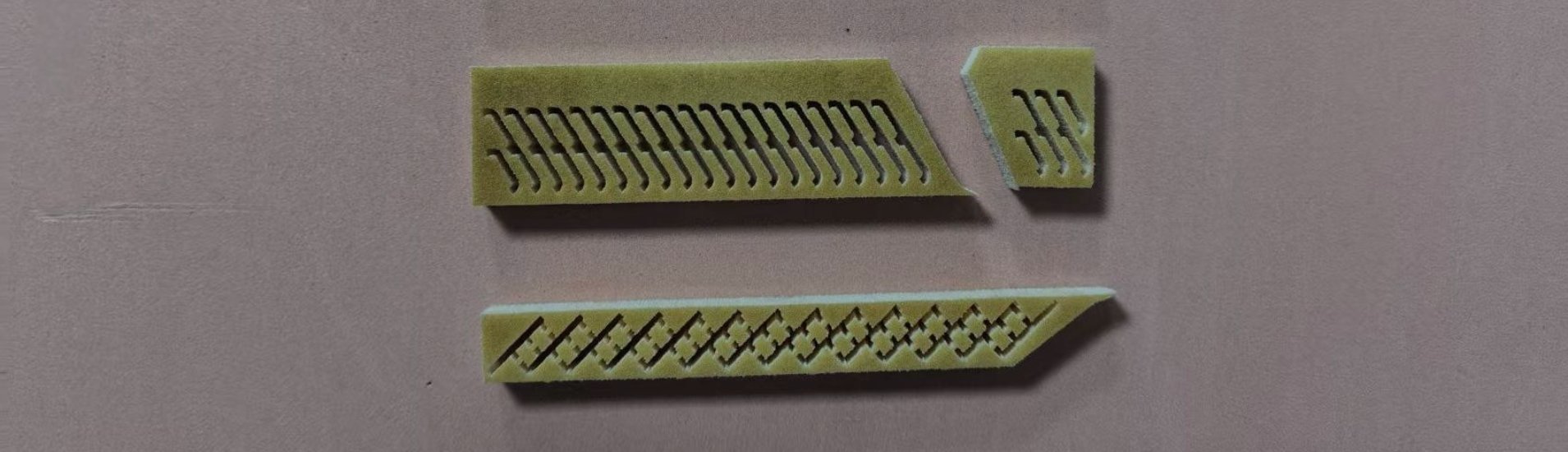

Waterjet cutting machines are extremely useful in the Job of dies-making. They can be customized to produce ejection rubber in any shape you require, meeting your specific die-making customization needs.

- Specifically designed for cutting soft materials such as ejection rubber, the cold cutting mode prevents material deformation.

- The workbench is reasonably designed, and the cutting head covers the entire area, preventing material waste.

- Semi-open gantry design, which is convenient for machine operators to place and collect materials and products.

- Water cutting machines do not require preheating and are ready to use immediately. The cutting medium is water, which is environmentally friendly and economical.

- Datasheet

| Waterjet cutting machine for ejection rubber | |

| Machine Model | AL-1106 |

| Cutting area(X*Y) | 1100×600mm |

| Z axis move distance | 40mm |

| Diameter of the Diamond tip | 0.17mm |

| Cooling system | Water cooling and Air cooling |

| Electrical Components | Schneider |

| Main pump motor | 7.5KW |

| Maximum Cutting pressure | 230 Mpa |

| Voltage and Frequency | AC 380V 50Hz |

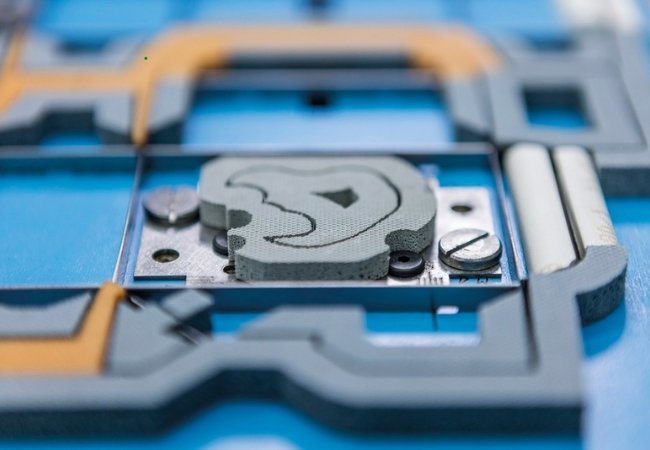

| CNC control system | WEIHONG NC65C |

| The best graphics formats | dxf.ai.dwg format |

Newest Waterjet CNC Control System

This waterjet cutting machine uses the latest well-known brand CNC control system. Simply design the rubber shape you need, generate drawings in software such as AutoCAD and AI, then import them into the machine control software, and the machine will cut the rubber sheet material.

The machine’s working area is 1100mm × 600mm. You can place materials of this size, with almost no thickness restrictions. Thanks to the waterjet cutting machine’s high-pressure water cutting mode, there is no need to focus the beam; Simply adjust the waterjet cutting head to a suitable height to place and cut thicker materials.

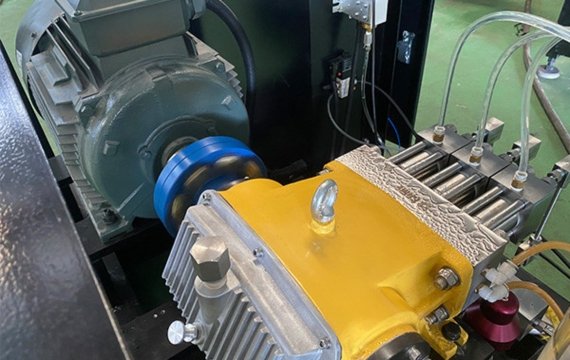

High Pressure Water Pump Maximum 230 Mpa

Our waterjet cutting machine uses a high-quality water pressure pump body, which can ensure long-term stable water pressure output. So there is no need to worry about the machine not being able to cut through thick materials.

With a maximum water pump output pressure of 230Mpa, it can not only ensure easy cutting of ejection rubber, but also cutting of other hard materials such as glass and stone.

High-Precision Waterjet Cutting Head

This waterjet cutting machine ensures cutting accuracy of >±0.1mm through precision control in several aspects. On one hand, it uses a waterjet cutting head equipped with a gemstone nozzle, which has a spray diameter of 0.17mm. On the other hand, the waterjet cutting machine uses a gantry-milled alloy aluminum semi-open beam to ensure high movement accuracy of the X and Y-axis.

Unlike other cutting equipment such as laser cutters, the waterjet cutting head does not require consumables like optical lenses. It cuts using water as the medium, eliminating the need for additional consumable materials. As a result, the daily operating costs are extremely low.

Die-Making Related Equipment

Advantages of Waterjet cutting machines in the die-making industry.

1. Cold cutting characteristics: Particularly suitable for cutting soft materials such as die-making rubber pads, as rubber pads are prone to edge hardening, deformation, and thermal stress when exposed to heat. Unlike laser cutting, which generates high temperatures that can burn edges, harden rubber materials, or create slag and thermal stress deformation. Waterjet cutting preserves the elastic force of the raw rubber material. Additionally, waterjet cutting edges do not produce burrs like those generated by purely mechanical cutting or laser cutting.

2. Waterjet cutting has no thickness limitations. Unlike laser cutting, which requires appropriate focal length and higher power to handle thicker materials. The waterjet cutting does not require focal length adjustment and can cut extremely thick plates (e.g., 25mm, 30mm, 40mm ejection rubber). This allows you to not only easily handle the production of flat die rubber pads but also the production of rotary die rubber pads.

3. Waterjet cutting machines utilize fully automatic CNC control systems for cutting, ensuring high precision while also enabling software-controlled cutting of complex geometric shapes. They can effortlessly handle any complex contours, making them an ideal choice for cutting irregular shapes, sharp angles, and small-scale structural die-cutting rubber pads.