Pneumatic Steel Rule Pliers for TIG or Laser Welding Model: AL-218A

As an essential pneumatic tool in the cutting die-making industry, this pneumatic plier has the following advantages and features:

- Uses well-known brand cylinders with a cycle life of over 1 million times. Long service life and maintenance-free for life.

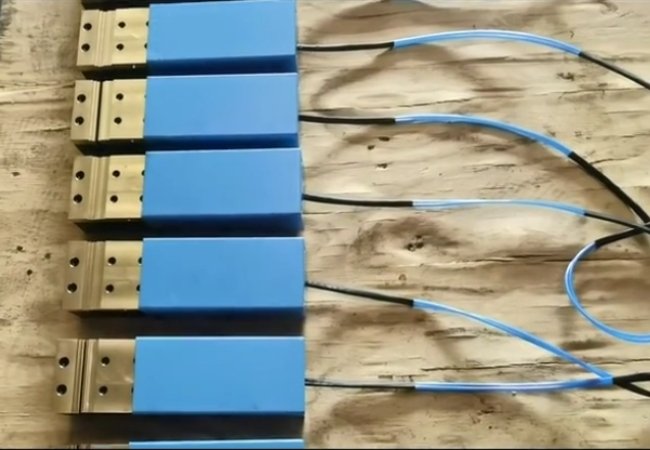

- The clamping tools are made of brass, which does not rust or corrode. Whole piece formed by a CNC machining center for high precision.

- The out shell is made of sheet metal bent into shape and coated with pain. Which not only protects the safety of operators during fixture movement, but also prevents dust and rust.

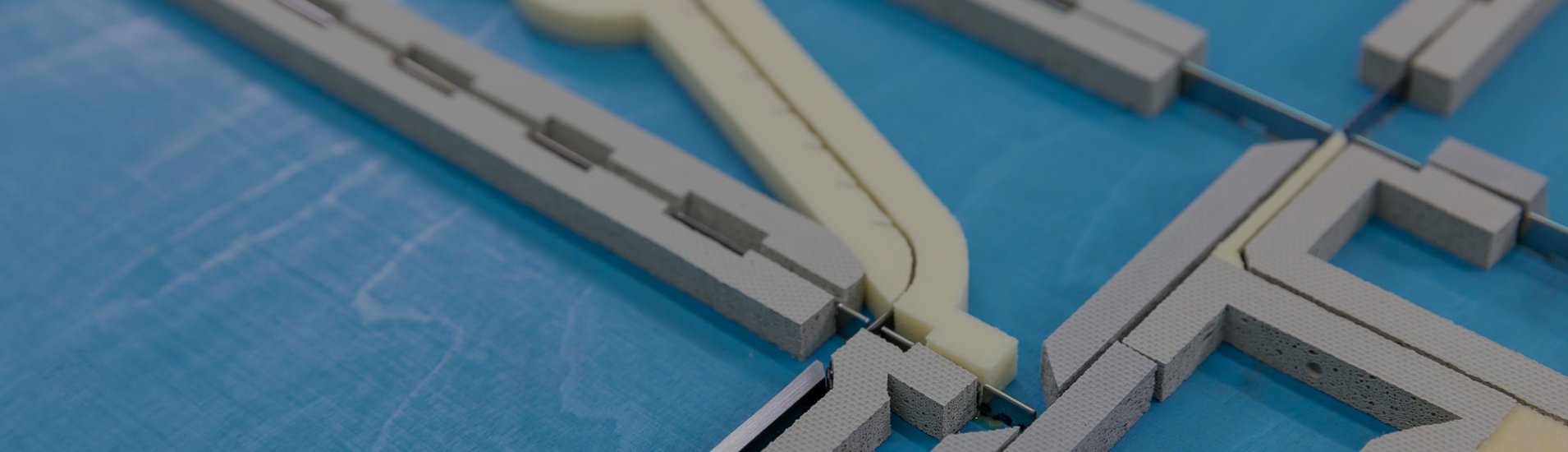

- The front end of this pneumatic clamp features a modular design that allows for the addition of different heights and shapes of clamps, such as F-shaped upper clamps for laser welding.

- Datasheet

| Pneumatic steel rule pliers for welding hold | |

| Model | AL-218A |

| Supported Rule Thickness | 0.45mm(1pt)-0.71mm(2pt)-1.07mm(3pt)-1.42mm(4pt) |

| Supported Rule Height | 8mm-100mm(all match) |

| Standard function | Hold the steel rule to assist welding |

| Working mode | Pneumatic(0.6-0.8Mpa compressor to support) |

| Machine Size | 380x98x60mm |

| Package Size | 400×102×65mm |

| Net Weight | 3KG |

| Gross Weight | 4.5KG |

Die-Making Related Equipment

The Application and Role of Pneumatic Pliers in the Die-making Industry.

- Pneumatic pliers significantly improve the efficiency of the welding process following the forming stage of automatic steel rule bending machines. Compared to traditional manual screw clamping pliers, pneumatic pliers utilize compressed air to achieve instant clamping and release. This significantly reduces the time required for workpiece replacement and clamping, markedly improving fixture utilization and welding efficiency per unit time. It also includes a foot-operated pedal as a one-touch switch, allowing operators to position the steel rule to be welded using both hands and foot while simultaneously operating the welding torch.

- Pneumatic pliers can also improve the stability of the clamping steel rules to increase welding precision. The pneumatic pliers system provides stable, uniform clamping force. This ensures that the workpiece(bent steel rule) does not undergo even slight displacement or vibration throughout the welding process (such as laser welding). Thereby guaranteeing the precision,consistency and dependability of the weld seam.

- Compared to manual steel rule pliers, pneumatic pliers are controlled by cylinders. This enable automated and integrated welding applications. We can connect the cylinder switch signal of the pneumatic pliers to the control board of the automatic laser welding machine. This allows the laser welding machine to control the sequence and timing of clamping and releasing through programming. This makes fully automatic or semi-automatic welding of die steel rules come true.

Send Your Inquiry Now