AL-52CN Blade Bending Machine for Die-making

This bender is suitable for someone who need to bend blades over 32mm height, such as 50mm blade and 60mm blade.

- Wide size range of die blades adaptation 32mm-60mm

- Special reinforced molds it can bend thicker blades

- Customizable design to combine different functions

- Humanized design control software Support different languages

The blades elevator for different size of blade storage

If you are using a lot of blades and need to switch back and forth every day to use different height or thickness blades. If you have a lot of blades and need to switch back and forth between different blade heights or thicknesses every day. The two standard blades coil holder won’t be able to satisfy your needs. So this fully automatic elevator will be very convenient for you to use.

Is it easy to use? My answer is yes, because it is fully automated, controlled by a CNC control board that allows you to select the layer you need with a single click. With a total of 6 layers, you can place different sizes of blades on each layer. If you need to use one of the blades, you can switch between them at the touch of a button. The elevator will automatically up and down to that layer. See the video on the left for more details!

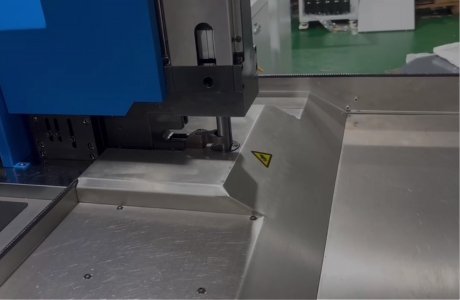

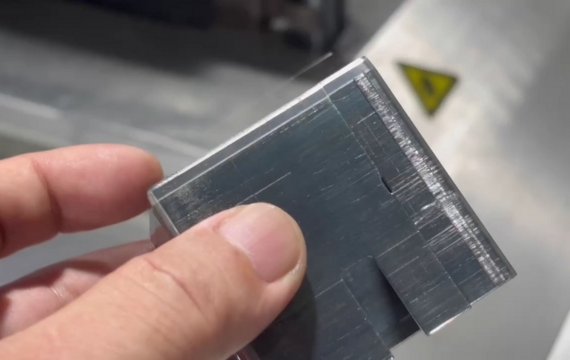

Straightly pre-cut by molds

Many customers who use the older types of blade bending machines have given feedback that none of the bending machines on the market have a cut-off feature that cuts particularly straight. In fact, this is not caused by the manufacturing process of the machine. It is decided by the machine’s cutting method . Conventional steel rule bending machines usually use the upper and lower scissors to cut. But the blade clamping process makes the blade and scissors can not maintain perfect vertical. That why after cutting, the cut edge will not be perfectly straight.

Our new bending machine uses an internal mold pre-cut. to ensure a perfectly straight cut. The front and rear ports can even be aligned perfectly without the need for a hawser.

Bending and Cutting off at the same rotary rod

Being the most fashionable cutting method nowadays, bending and cutting are in the same working station combined at one rotary rod. This cutting method has 3 biggest advantages,

1. Cutting and bending in the same station, you can reduce the probability of machine jamming or error. Because we need more special sensors for different machine movements .

2.Cutting and bending in the same station, can greatly improve efficiency. It not only reduces the machine’s feeding action, and also delete the upper and lower scissors shear action.

3.Cutting and bending in the same station, working with the mold pre-cutting at the same time. This way can ensure the verticality of the cut-off function, making the head and tail connection more perfect.

- Data sheet

| AL-52CN blade bending machine | |

| Machine Model | AL-52CN |

| Blade (thickness) | 0.71-1.05mm-1.42mm(2pt 3pt 4pt) |

| Blade (height) | 23.8-60mm(common size like 50mm,60mm) |

| Max Bending R | 100° |

| Min R in 90° | 2 |

| Min U shape bending size | 5mm |

| Minimum bending size on front/back | 2-3mm depends on the blade thickness |

| Standard functions | Cutting,bending,bridging,lipping(Nicking option) |

| Blade feeding accuracy | ±0.02mm |

| Bending Flatness | 0.1/100mm |

| The way of cut | Bending and Cutting at one Rotary Rod |

| Gas supported | 0.6-0.8Mpa compressor air |

| Voltage and Frequency | AC 220V 50Hz |

| Gross Power | 2.5 KW |

| Machine Size and Weight | 230CM*75CM*165CM 520KG |

| The best graphics formats | dxf.ai.dwg format |

Other main features of AL-52CN die blade bending machine

Compared to conventional blade height bending machines, the 52CN is designed for blades with a height of 32-60mm, such as 50mm and 60mm. And the blade thickness also has higher adaptability, 2pt-3pt-4pt all can work.

Often some special industries need to use high knife blade cutting, such as thick pearl cotton products, EVA packaging liner, and other thicker composite multilayer material industries. These industries usually need to use 50mm or 60mm height blade dies for punching. Our 52CN will be a great choice.

As we all know, it is very difficult to bend and form 3PT and 4PT because the bending force requires are strictly higher after thickness increasing. The 52CN bending machine uses higher power and torque servo motors on the one hand, so that it can bend and cut 3pt and even 4pt die blades more easily. On the other hand, the mold is specially hardened to prevent the problem of the blade can’t be bend and cut because higher hardness and thickness.

The footprint is very small, approximately 230cm x 75cm x 165cm (L x W x H)

- 220V single phase 50Hz total 2.5Kw, 12A power supply

- An air compressor with 1.6-0.8Mpa pressure

It is not possible to match all heights of blade when the thickness is 4PT only the machine only matches 23.8mm blade, because 4pt blade hardness is too high. But we have specialized special models to choose for 1.42mm or 2mm thickness blades, please click AL-100A for details:

| Model | Steel Rule | Bending | Cutting | Bridging (3/6mm) | ||

| AL-52CN | 0.71*23.8-60mm | OK | OK | OK | ||

| 1.07*23.8-60mm | OK | OK | OK | |||

| 1.42*23.8mm | OK | OK | OK | |||