Carton Box Sample Maker Cutting Machine Model: AL-2516E AL-1813E AL-1510E AL-1007E

As one of the most professional supplier of printing and packaging industry equipment, we have come into contact with thousands of customers in the industry. Based on your needs, we have optimized the structure and configuration of the machines.

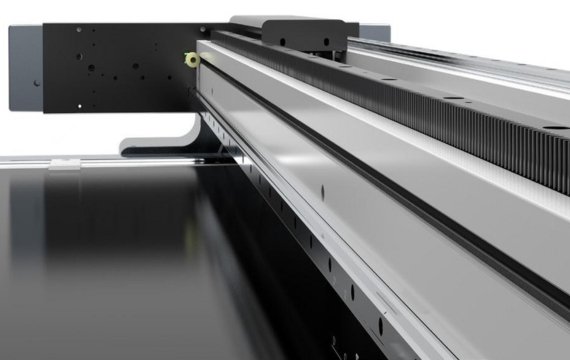

- The fully cast aluminum X-axis crossbeam is highly lightweight, enabling the machine to operate and cut at very high speeds.

- Not only does it focus on quality, but its exterior design also pursues simplicity and ergonomics. The minimalist workbench edges make it convenient to place materials and collect finished products.

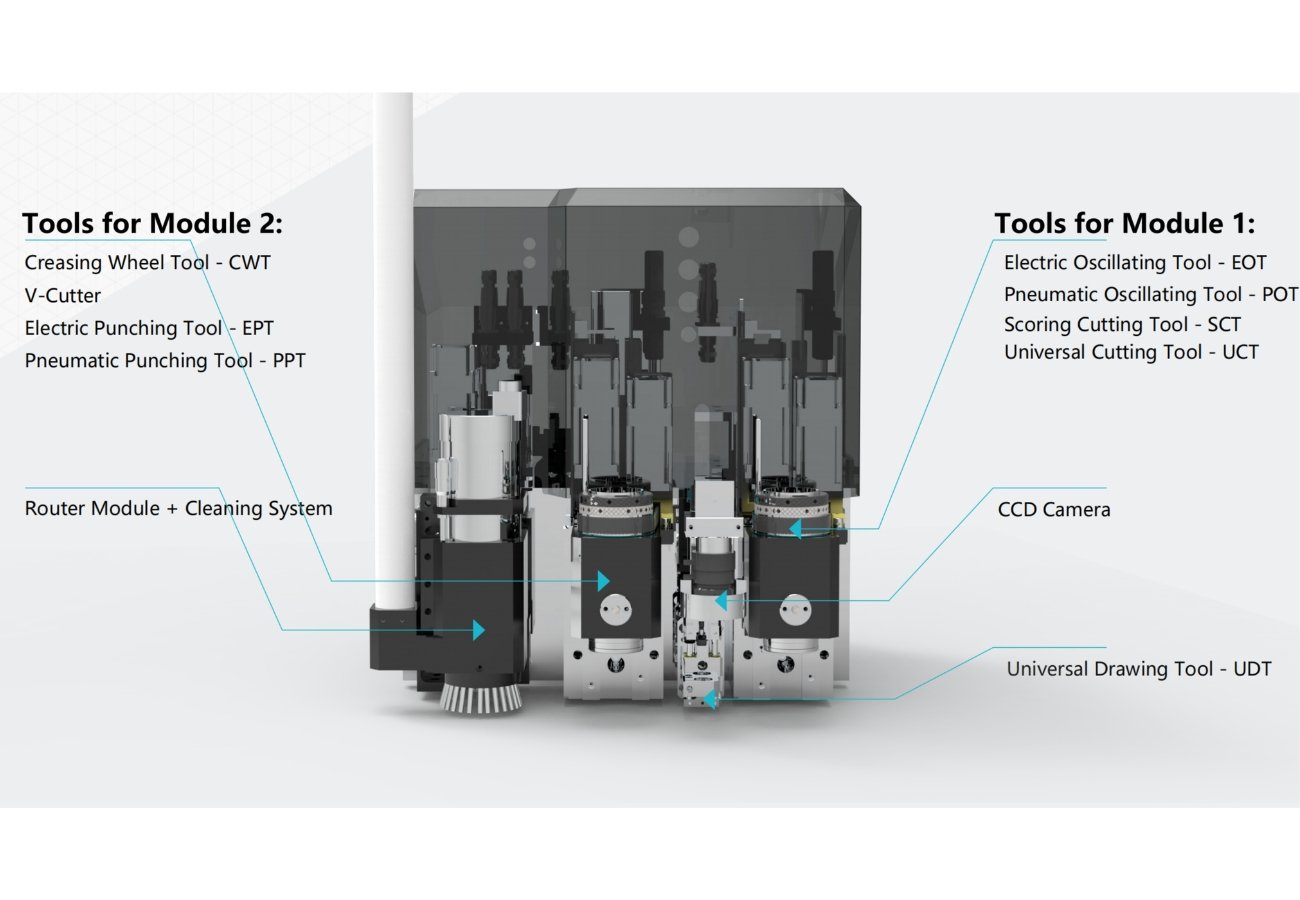

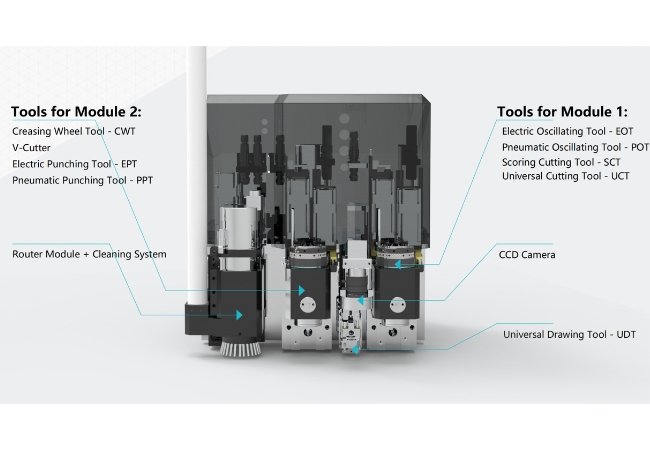

- We have more than 12 different types of processing heads. Please contact us to discuss your exact requirements especially what kind of functions you like.

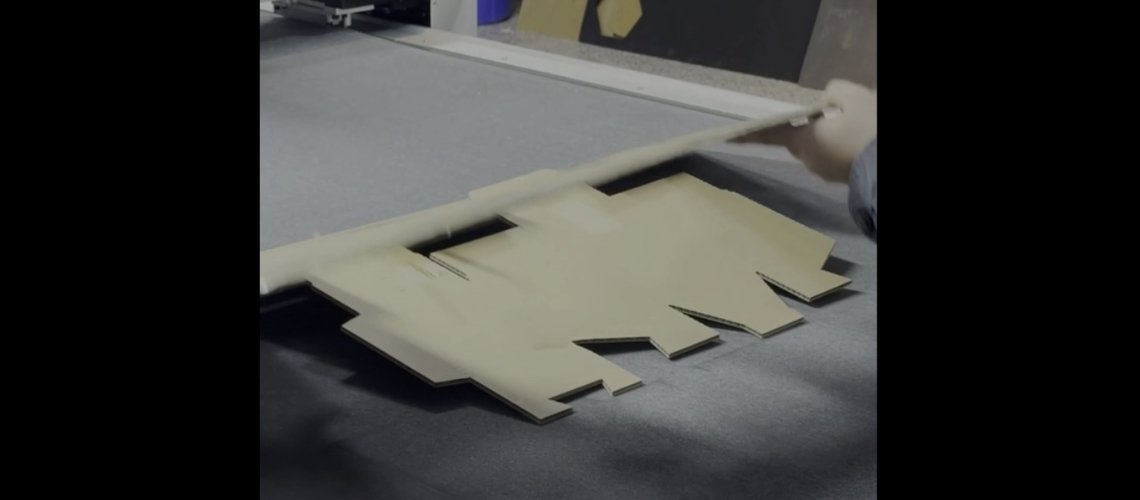

- We specialize in the die-making and printing packaging industry. We keep optimizing machine installation and commissioning processes to ensure consistency between sample made by this carton box sample maker cutting machine and die-cut products.

- Datasheet

| Carton box sample maker cutting machine | ||||

| Machine Model | AL-2516E | AL-1813E | AL-1510E | AL-1007E |

| Cutting area(X*Y) | 2500×1600mm | 1800×1300mm | 1500×1000mm | 1000×700mm |

| Cutting Speed | 0-1300mm/s | 0-1300mm/s | 0-1300mm/s | 0-1300mm/s |

| Cutting Thickness | 0.1-50mm | 0.1-50mm | 0.1-50mm | 0.1-50mm |

| Applicable Materials | Corrugated Cardboard, Folding Packaging, Labels,Foam, Sponge, Preprinted Board, Acrylic, Honeycomb,Fabric, Leather and other soft materials, etc. | Corrugated Cardboard, Folding Packaging, Labels,Foam, Sponge, Preprinted Board, Acrylic, Honeycomb,Fabric, Leather and other soft materials, etc. | Corrugated Cardboard, Folding Packaging, Labels,Foam, Sponge, Preprinted Board, Acrylic, Honeycomb,Fabric, Leather and other soft materials, etc. | Corrugated Cardboard, Folding Packaging, Labels,Foam, Sponge, Preprinted Board, Acrylic, Honeycomb,Fabric, Leather and other soft materials, etc. |

| Gross Weight of the machine | 1130kg | 850kg | 750kg | 650Kg |

| Transmission System | linear guide,gear rack with servo motor | linear guide,gear rack with servo motor | linear guide,gear rack with servo motor | linear guide,gear rack with servo motor |

| Metarials Hold-down Method | Intelligent vacuum partition absorption control | Intelligent vacuum partition absorption control | Intelligent vacuum partition absorption control | Intelligent vacuum partition absorption control |

| Machine Power supply | AC 380V+10%,50+10% HZ | AC 380V+10%,50+10% HZ | AC 380V+10%,50+10% HZ | AC 380V+10%,50+10% HZ |

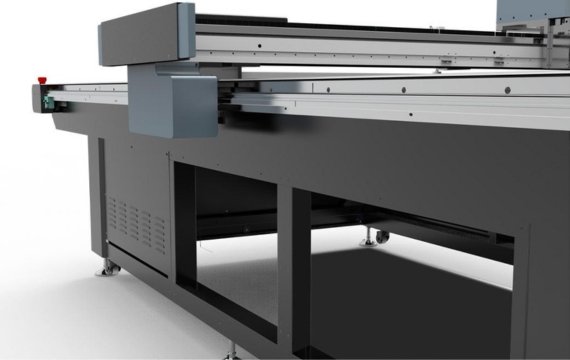

High-strength and Sturdy Machine Frame

The machine body structure uses integrated extruded profiles welded into shape.Which are not only sturdy and durable, but also undergo oxidation treatment to ensure that they will not rust or deform over time.

The sturdy machine base also ensures the overall stability of the X axis crossbeam when working with the servo motor, preventing vibration and shaking. Combined with limit sensors at various positions, it ensures safety during machine operation.

Most Advanced Transmission Method

Our carton box sample maker cutting machine also uses the most advanced transmission method currently available on the market. It features a dual-drive rack and pinion system with precision guide rails, paired with a high-power Y-axis servo motor. The maximum operating and cutting speed can reach 1300 mm/s, which is more than 50% faster than traditional ball screw and stepper motor systems.

The guide rails are mounted on the side of the machine frame, effectively saving horizontal space and making the Y-axis edge extremely narrow. This not only looks aesthetically pleasing but also gives the machine a sleek, minimalist appearance. Additionally, the parallel structure of the rack and guide rails significantly enhances transmission efficiency.

Intelligent Vacuum Partition Absorption Control

Self-developed and manufactured intelligent vacuum partition absorption control system. The adsorption function in certain areas ensures strong adsorption effects and prevents material displacement during cutting. On the other hand, it enhances adsorption force within the area, effectively fixing thicker materials such as 50mm EVA.

Additionally, the work platform offers two types to choose from: a flat table and automatic roll material feeding. During roll material cutting, the adsorption function moves to the cutting area based on the cutting head’s sensors, preventing material displacement.

Die-Making Related Equipment

The principle of oscillating knives cutting machine, the functions of various processing tools, and the materials they can be applied.

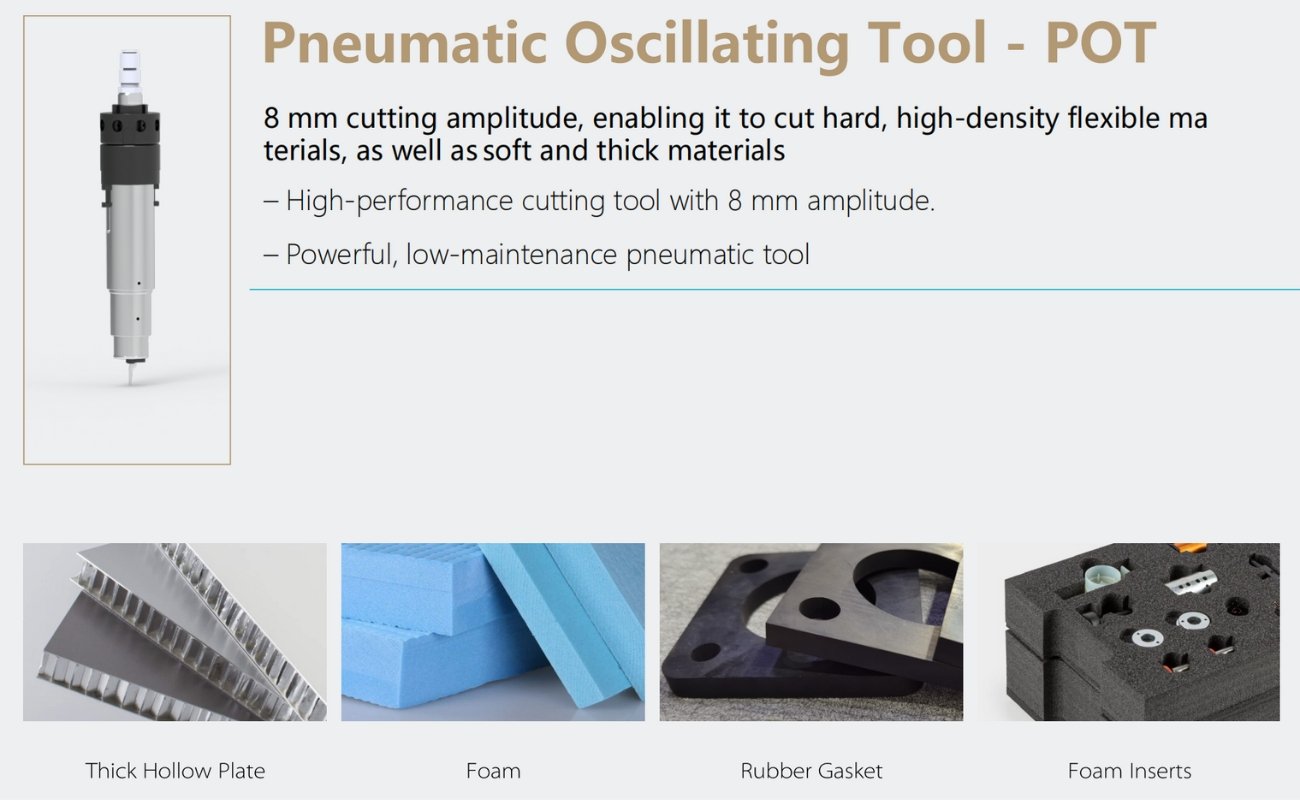

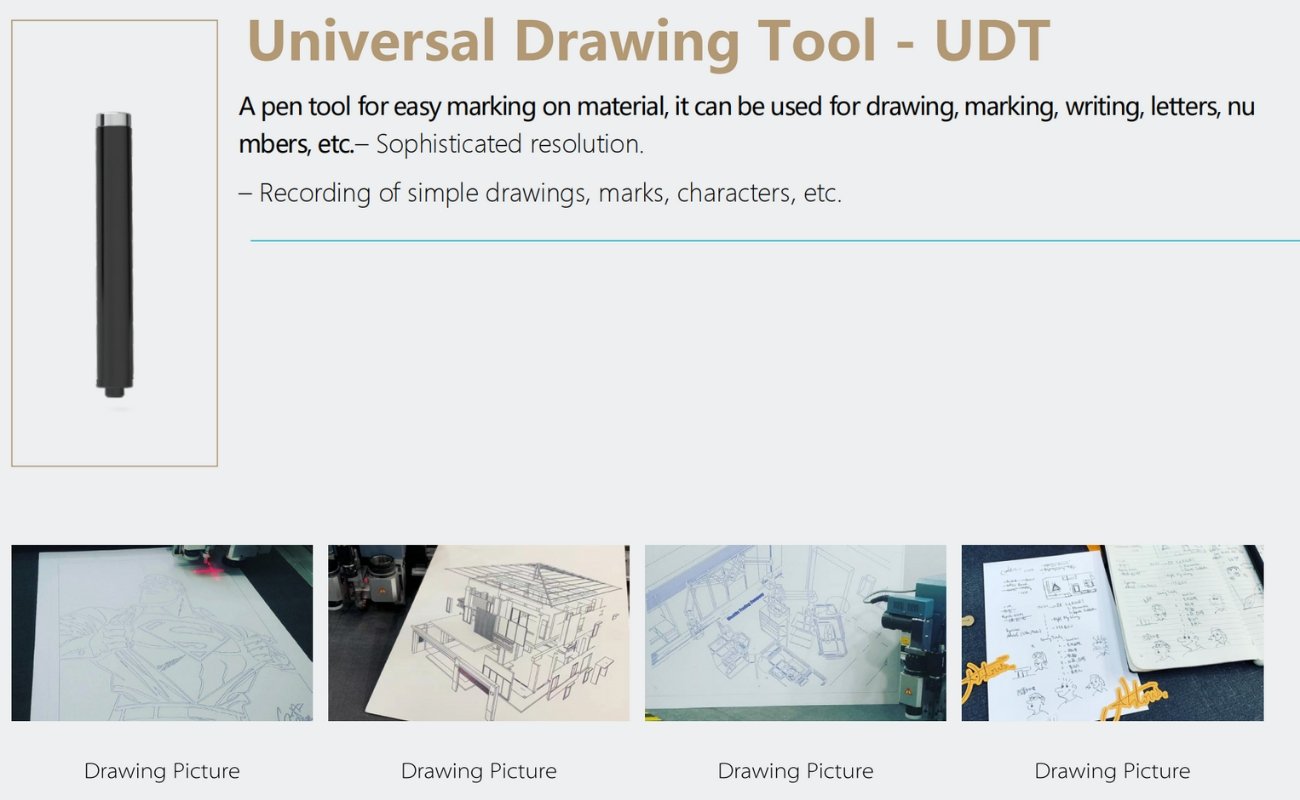

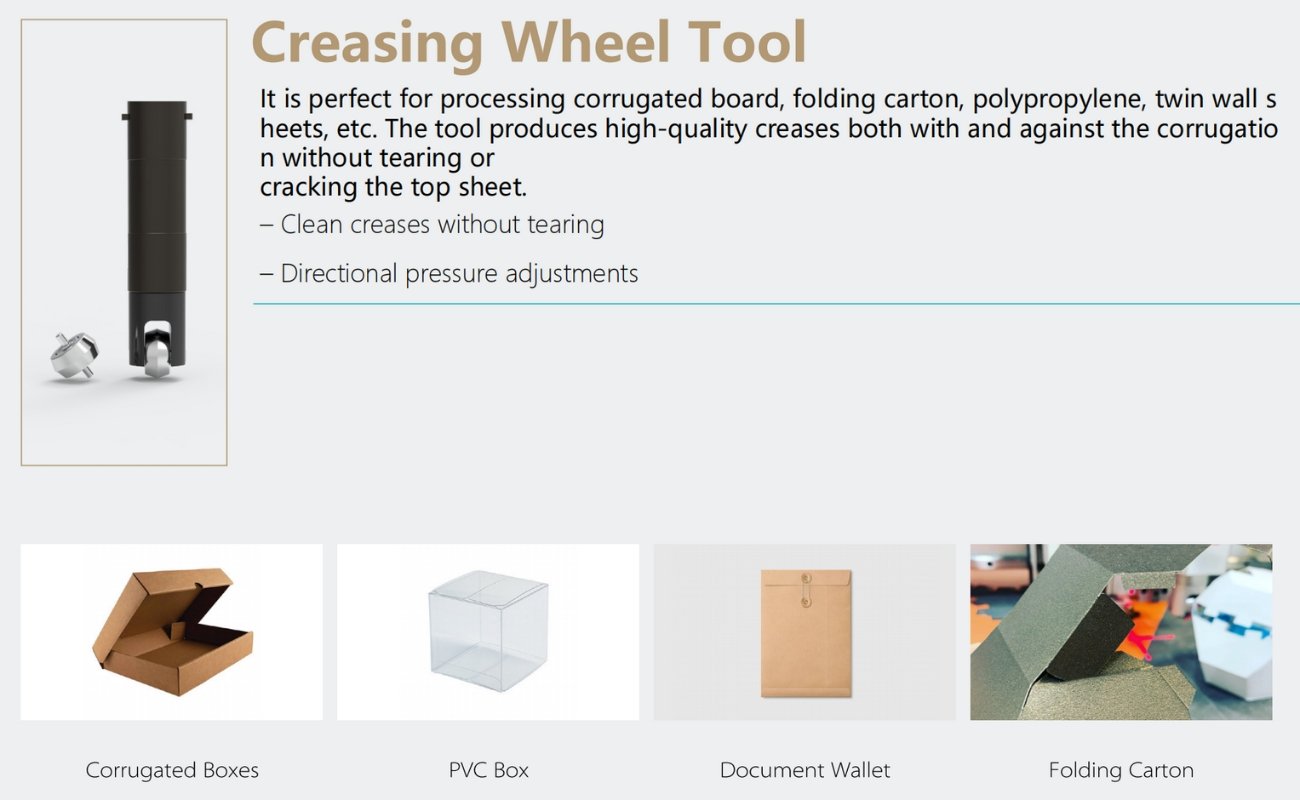

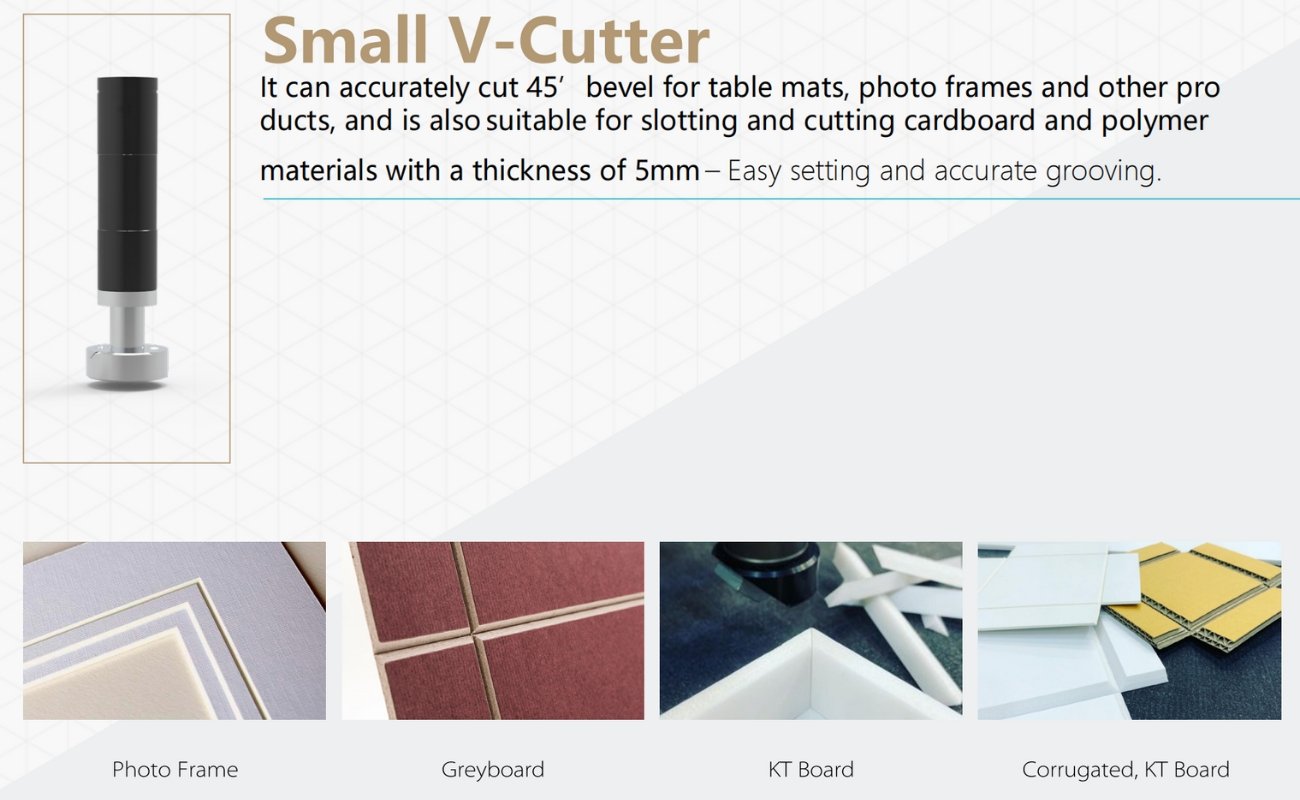

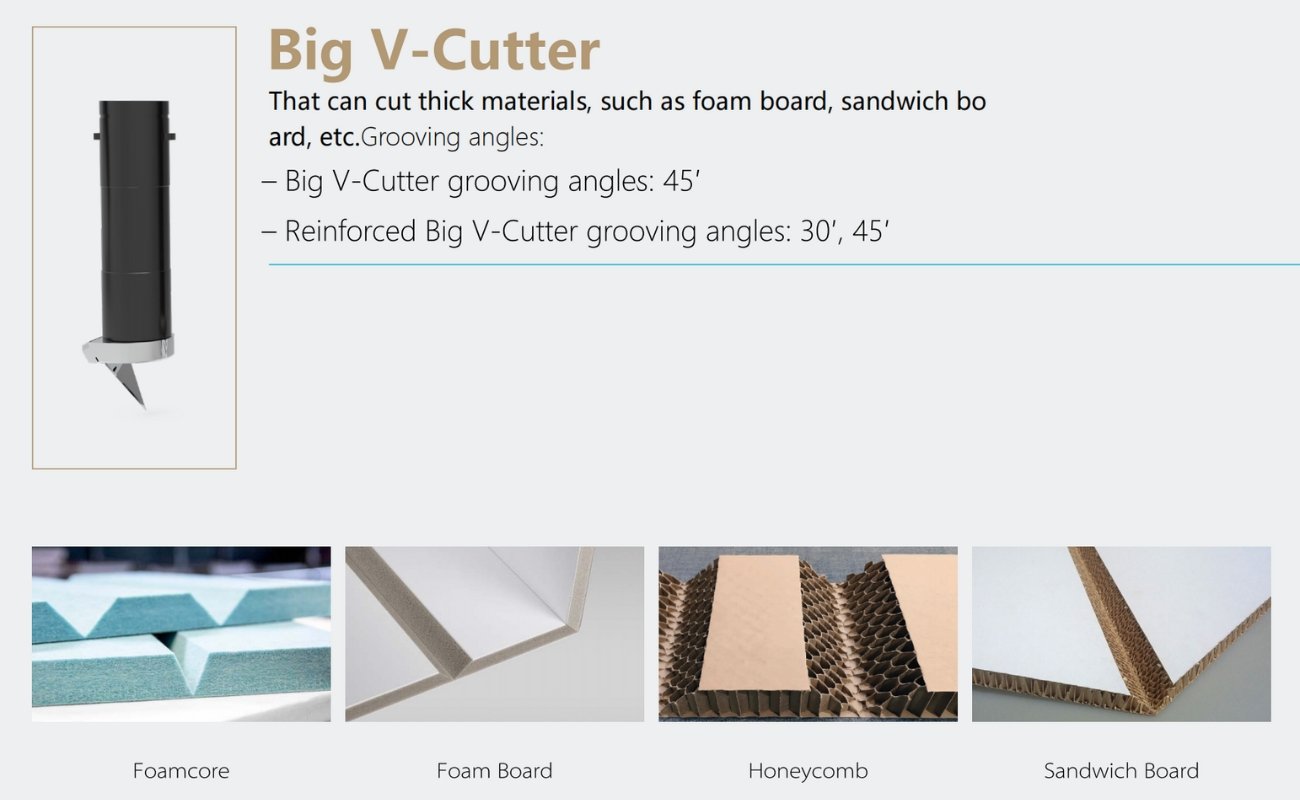

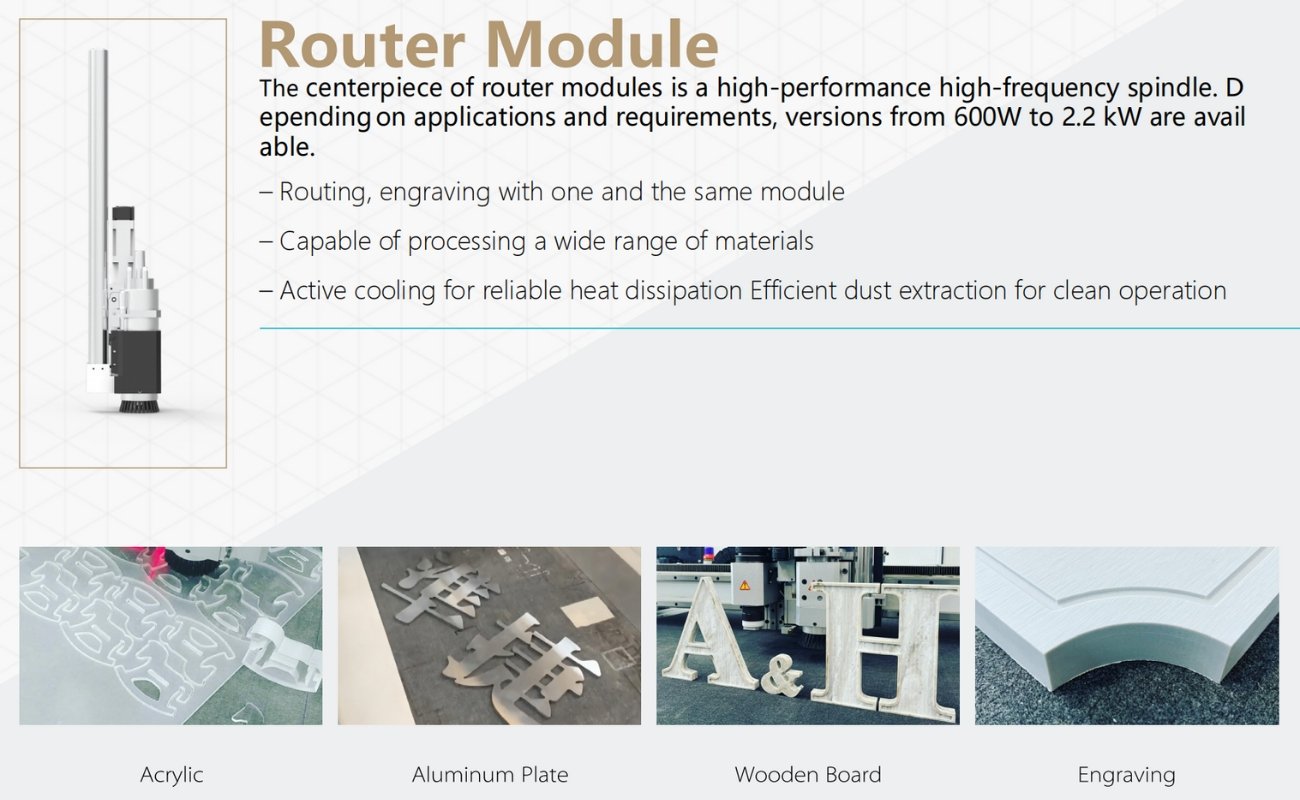

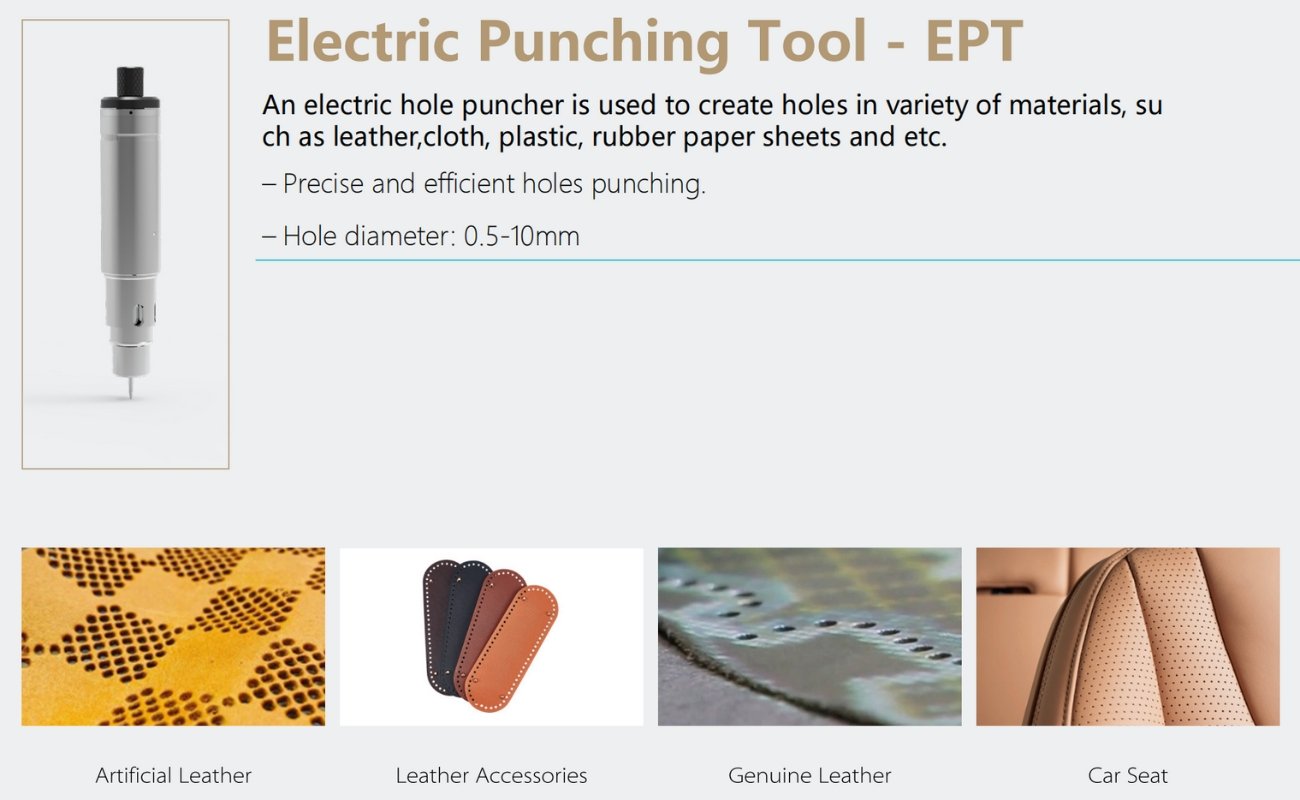

Our carton box sample maker cutting machine is actually an oscillating knife cutting machine. The main feature of this machine is that it is non-thermal cutting type, which does not burn the material. It employs servo and rail drive systems, ensuring high precision. The machine is suitable for a wide range of materials (almost all flexible materials can be applied). Its primary operating principle involves a high-speed oscillating knife head, which typically oscillates at frequencies ranging from several thousand to tens of thousands of times per minute in an up-and-down motion to achieve cutting. Additionally, oscillating knife cutting machines can be equipped with various types of processing tools. Different tools designs are tailored to accommodate distinct material properties, cutting requirements, and desired outcomes. Common processing tools include electric oscillating tool(EOT), pneumatic oscillating tool(POT), scoring cutting tool(SCT), V-Cutter, and electric punching tool(EPT),Etc.

The powerful functionality of a oscillating knife cutting machine mainly depends on the selection of the appropriate knife tools. It is essential to understand the characteristics and suitable applications of each processing tools, and to combine this knowledge with specific material and processing requirements in order to fully leverage the machine’s capabilities and achieve high-quality, high-efficiency cutting. Typically, operators need to do cutting test based on actual conditions (especially when material type and thickness changed), adjusting parameters such as processing tools type, knife height, and cutting speed to achieve optimal performance.

To make it easier for you to use this machine on a variety of different materials, our whole cutting head features a multi-module design that allows you to easily change the processing tool as needed. To learn more about the processing tools available for our carton box sample maker, their functions, and the materials they can be applied on. Please refer to the following processing tools categories and functional descriptions. Or Contact us for the machine brochure!