Die Board Laser Cutting Machine

As one of the necessary equipment for the production of wooden cutting dies, high power laser cutting machines have following features:

- 1500W-2000W-2500W super high laser power for choice

- 1220×2440mm working area matches standard plywood die board size

- High speed ball screw rod transmission system with servo motor

- Automatic focus laser head can cut the 1pt 2pt 3pt 4pt seam at the same board

Heavy duty machine base frame

The whole machine is welded with thickened steel plate to ensure the stability of the machine base foundation, not afraid of the vibration caused by the movement of servo motors, and the weight of the whole machine is more than 4T.

The Y-axis mounting surface of the die board laser cutting machine has been milled twice by gantry milling to ensure cutting accuracy and repeat positioning accuracy of ±0.05mm.

High power fast-axial-flow Co2 laser source

Aolang laser die cutting machines adopt name brand CO2 laser generator NT or BY, laser power 1500W-2000W-2500W optional. The laser energy is powerful, can cut 4PT blade seam only one time cutting.

Powerful laser power can also ensure the cutting speed of the machine. On the basis of our test,the cutting speed of the machine as follows, 1500W: 2M/min 2000W: 2.5M/min 2500W: 3M/min. Please select the laser power according to your needs.

Setting the steel rule slits width in the software

Aolang die board laser cutting machine with smart control system and laser cutting head, you can cut different steel rule installing slits on the same wooden die board.

Its principle is through the control system and intelligent laser head information interaction. You set up the width of the slit width you want in the control software, then the laser head receives the signal. The will automatically recognize and adjust the laser head focal length to match the width of the different cutting slit.

Intelligent laser cutting head with anti-crash function

Maybe you are still worried that the laser head has risk to lose the support of the bracket and crash and incur large repair costs.Do not worry, AOLANG Laser has upgraded the laser head of our die board laser cutting machine with a intelligent laser head.

In case that your machine’s laser head fall down from the die board, it will automatically stop the machine and raise the laser head to prevent crashing accident.

- Data sheet

| Die Board Laser Cutting Machine | |||

| Machine Model | AL-1325- 1500W | AL-1325-2000W | AL-1325-2500W |

| Working Area | 1220×2440mm | ||

| Laser Power | Fast-axial-flow laser generator 1500W | Fast-axial-flow laser generator 2000W | Fast-axial-flow laser generator 2500W |

| Laser Head | Autofocus laser head(can cut 1pt 2pt 3pt 4pt at the same board) | ||

| Cutting Speed(18mm die board) | 2M/min | 2.5M/min | 3M/min |

| Cutting thickenss | 1-25mm Plywood die board | ||

| Laser Path | Gantry/Flying Laser Path | ||

| Transmission System | Ball Screw Drive with Servo Motors | ||

| Control System | Aolang laser developed PA system | ||

| RAM(Random Access Memory) | 32GB Supports Offline | ||

| Power supply | 380V/50HZ 30KW | 380V/50HZ 33KW | 380V/50HZ 35KW |

| Repeated Positioning Accuracy | ±0.05mm | ||

| Cooling Type | Water Cooling(Pure water, antifreeze in the winter) | ||

| Assisted Gas of the Laser Head | Compressed air (0.4-0.8Mpa) | ||

| Assisted Gas of the Laser Source | He, N2, CO2(99.99%) | ||

| Graphic Format Supported | CAD; PLT; CDR; AI;Etc | ||

Die board laser cutting machine,a core equipment of die-makers.

High-power laser die cutting machine is one of the key equipment in the die-making industry, if you want to make wood cutting dies, acrylic cutting mold, even shoe knife mold, it is one of the key equipment too, it not only can cut the common plywood die template, but also can cut the acrylic board well, even the thin steel and stainless steel board. (more detail please check our blog: how a Co2 laser machine can cut a metal material?) And the wood cutting dies and other types of dies are widely used in printing industry, corrugated box packaging industry, advertising trademark industry, blister industry, leather shoes industry and so on. I am sure that the die board laser cutting machine will be the biggest help for your die-making business grows.

If you are already experienced in making dies with hand tools such as chainsaws, laser die cutting machine can make a big difference in the quality of your cutting dies. Because of that Aolang high laser power die cutting machine using CNC control and high-precision ball screw for transmission,it not only can cut the die board with a fast speed and high efficiency, but also can make your dies high precision, blade installing seams are all uniform.

A fast-axial-flow Co2 laser generator will come with the machine, the laser generator is powerful and stable laser output, can cut the common standard 18mm plywood die board at a speed of 100-120 meters per hour. It can also work on thicker die boards up to 25mm thickness. Powerful laser output ensure that the machine can cut 4pt slit with one pass.

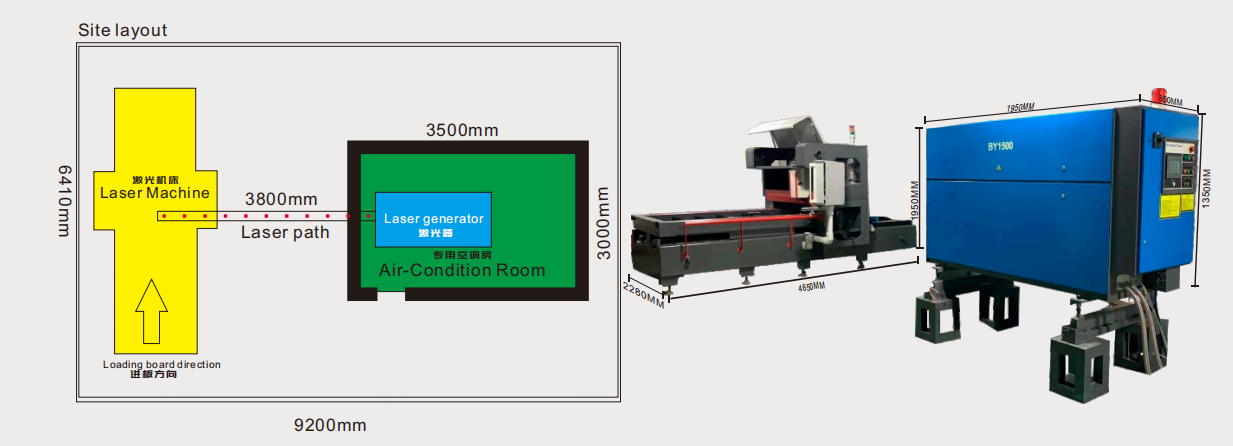

Our suggestion is your workshop area is not lower than 9200×6410mm.

380V 3 phases power supply 40A

Stable and good level ground to put the machine

A small room for the fast-axial-flow laser generator with air-conditioner

- Daily cleaning is required to keep the machine and generator clean

- One month to put butter or grease for the ball screw rod

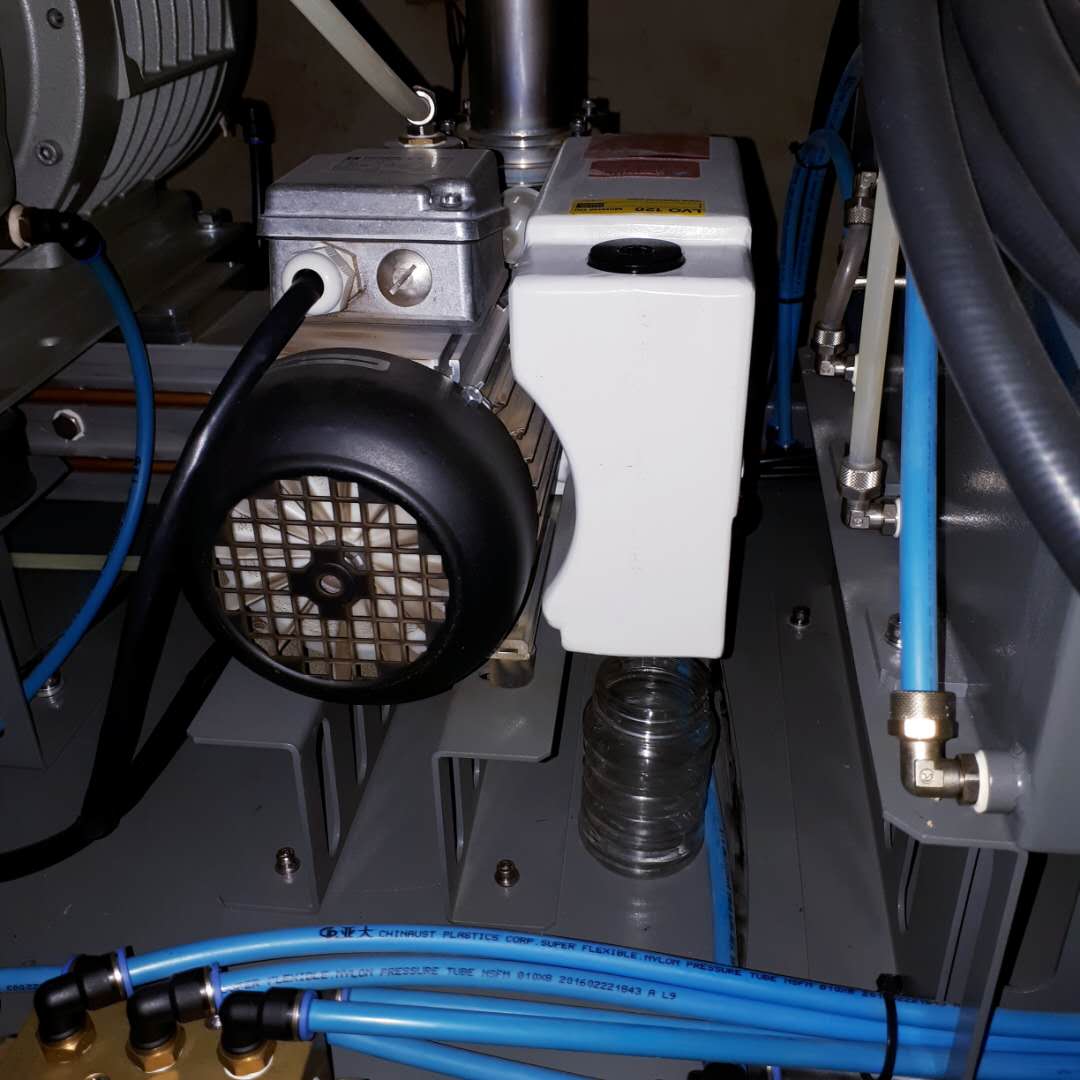

- Fill the oils for the roots pump and vacuum pump of the laser generator when it lower than the warning level