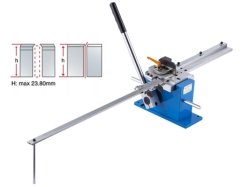

Manual European Type Steel Rule Bridging Machine Model: AL-209

Bridging is a necessary step in the die-making processes. This European type steel rule bridging machine can help you control the precision of bridging process.

- Better structural design, built-in measuring ruler to ensure accuracy.

- The steel rules have a larger placement surface, which can effectively ensure the force-bearing area of the blade and avoid burr generation.

- Compared to standard bridging machine that work with 1pt-3pt, European-style bridging machine can work blades with a maximum thickness of 4pt.

- The width and height of the bridge can be customized. Please contact us to discuss your requirements.

- The entire body is formed using a CNC machining center. Rather than cast iron, resulting in high precision quality.

- Datasheet

| European type steel rule bridging machine | |

| Model | AL-209 |

| Supported Rule Thickness | 0.45mm(1pt)-0.71mm(2pt)-1.07mm(3pt)-1.42mm(4pt) |

| Supported Rule Height | 8mm-32mm(customized) |

| Standard function | Bridging cutting |

| Tools Quantity(molds) | Bridging width 3-6mm customziable |

| Machine Size | 750x360x460mm |

| Package Size | 730×370×350mm |

| Net Weight | 24KG |

| Gross Weight | 26KG |

| Installation Method | Screwed to workbench |

Complete Guide

The role and importance of bridging in die-making industry.

In the manufacture of wood cutting dies , the bridge is a key structural design feature, primarily used to enhance die’s strength and ensure stability and precision during the punching or cutting process.

The basic structure of the cutting die is to fix the blade on the die board(wood,PVC,Acrylic). And then the wooden dies will be used for punching and die cutting. Therefore, it is necessary to design a bridge structure to support and fix the blade during the punching process. The bridging structure can also prevent the blade from breaking and deforming during the punching process.

Therefore, the importance of the support and deformation resistance of the bridge structure is shown in the following aspects:

- Extend the service life of the cutting dies. Typically, cutting dies are prone to blade chipping after frequent die cut punching, while a reasonably designed bridge can distribute stress and improve the durability of the dies.

- Ensure product accuracy. The bridge structure can reduces die deformation and avoids product dimensional deviations caused by die deformation (such as folding errors in packaging boxes).