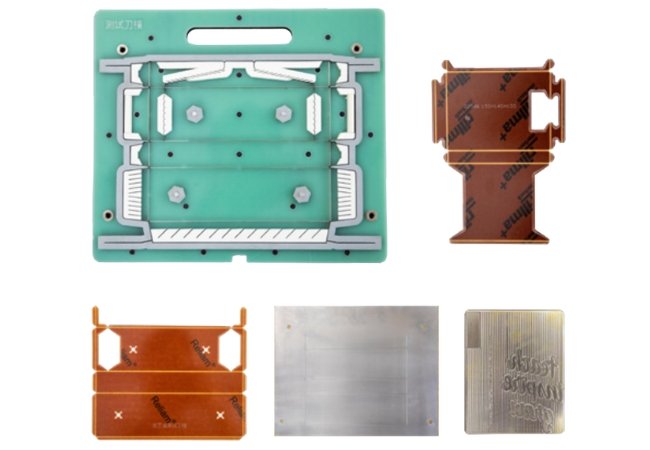

Fiber Pertinax Making Machine for Dies Bottom Base Model: AL-1100/AL-1209

Our pertinax making machines are manufactured to high standards and include a variety of practical and advanced features, with all components sourced from industry-leading suppliers.

- The entire machine body is made of marble material that meets the standards for testing equipment. This ensures the stability of the machine body and the accuracy of the horizontal level.

- The X, Y, and Z axes all use high-precision polished ball screws, enabling faster and more stable machine engraving operations.

- Both models use ultra-high speed engraving spindles and are controlled by an intelligent CNC control system, which not only enables automatic engraving but also automatic tool change for six sets of tools.

- The work table uses vacuum suction technology. Not only does it securely hold the material you need to engrave in place so that it does not move around while you are engraving, but it also has a certain degree of cleaning capability.

- Datasheet

| Pertinax making machine of die-making | ||

| Machine Model | AL-1100 | AL-1209 |

| Working area(X*Y) | 1100×1100mm | 1200×900mm |

| X.Y.Z axis move distance | X. 1100mm Y.1150mm Z.200mm | X. 1320mm Y.900mm Z.200mm |

| Driving system | Servo motor with Ball screw rod | Servo motor with Ball screw rod |

| Spindle Rotation Speed | 6000-40000 RPM | 6000-60000 RPM |

| Spindle Power | 1.8KW | 4.0KW |

| Spindle holder | TK-E11 | IS020 |

| Spindle Torsion | 1.0 NM | 1.6 NM |

| Applied Material | Fiber pertinax | Fiber pertinax and steel pertinax |

| Engraving Tool QTY | 6 pcs | 6 pcs |

| Tool Change mode | Auto change | Auto change |

| Tools Max diameter | 7mm | 12mm |

| Tool Max outside Length | 20mm | 30mm |

| Repeated Positioning Accuracy | ±0.05mm | ±0.05mm |

| Power supply | 380V 50Hz | 380V 50Hz |

| Control System | WEIHONG NC65C | WEIHONG NC65C |

| Machine dimensions and Weight | 1160×1700×1560mm 2000KG | 1750×2200×1620mm 2500KG |

| The best graphics formats | G,NC,UG,demo,iso,eng,dxf,cut,plt,txt | G,NC,UG,demo,iso,eng,dxf,cut,plt,txt |

Servo motor driving system

The entire machine’s traditional system uses servo motors and drives, combined with high-grade ball screws. On the one hand, this ensures the speed of the machine during rapid engraving. And on the other hand, the screw transmission ensures the repeat positioning accuracy of the pertinax making machine to be ±0.05mm.

Moreover, it is well known that the response speed of servo motors is within 10ms, which is much faster than stepper motors and other types of motors.

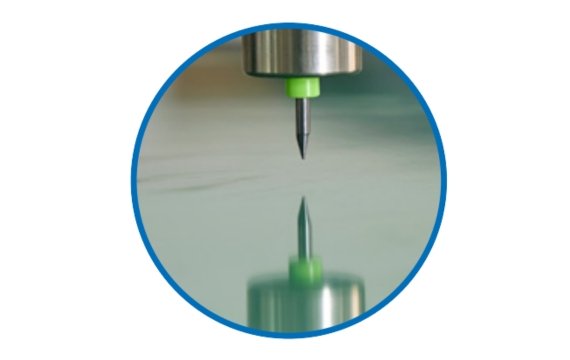

Automatic engraving tools change

This machine is equipped with six sets of engraving tools featuring different-diameter engraving tools, designed to accommodate various thickness specifications of upper cutting dies. Our machine features a fully automatic tool-changing system. Simply select the desired tool diameter in the software, and the system will automatically move the Z-axis spindle to the tool position. Then it select the appropriate tool, and securely fasten it in place.

This automatic tool-changing system not only significantly enhances the machine’s operational efficiency but also eliminates the need for manual tool changes. Thereby reducing the risk of employees being injured by the sharp tools.

6 pieces grilling tools

Both models include six sets of different engraving tools and can be automatically replaced when needed.

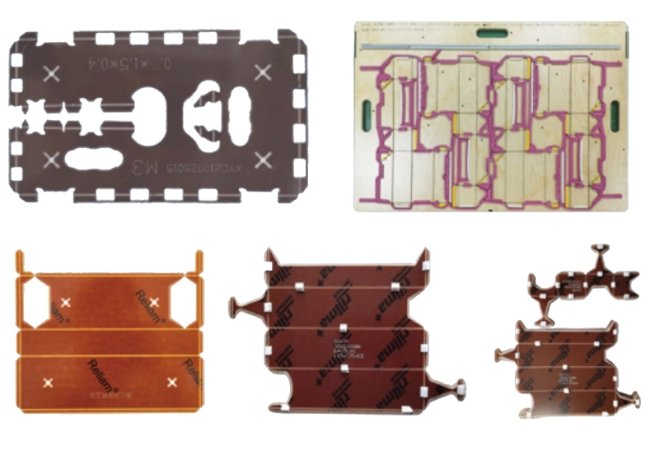

So why are different diameter heads needed? As we all know, a pertinax down side die is an auxiliary base die mainly used to support the upper die steel rule or assist in creasing rule when die cutting. Therefore, we need different diameter tools to match different steel rule thicknesses and creasing rule thicknesses.

Die-Making Related Equipment

What is the difference between two different models AL-1100 and AL-1209 of pertinax making machine?

The core functions of both pertinax making machines are the same, as they are both designed for engraving, cutting, and making die base(base cutting die). However, they still have different application ranges, primarily due to the following reasons:

1. There is a significant difference in the power and speed of the spindle. The spindle of the AL-1209 reaches 4000W, while the spindle of the AL-1100 is only 1800W. Therefore, we only recommend the AL-1100 for standard fiber pertinax. The higher-grade AL-1209, can be used not only for fiber pertinax engraving and cutting but also for plastic or steel pertinax base. Additionally, the difference in power determines the compatibility with different tool holders to match varying tool diameters. The AL-1209 can accommodate tool diameters up to 12mm. The AL-1100, due to its limited power,only has a maximum tool diameter of 7mm.

2. The workbench’s working area differs, allowing you to place materials of various sizes. The AL-1209 has a working area of 1200×900mm, while the AL-1100’s workbench area is limited to 1100×1100mm. You can select the appropriate model based on the size of your materials.

3. Additionally, due to the application material range limitations of each model, the AL-1209 can be equipped with a local water cooling or air cooling system during engraving as metal friction generates significant heat when engraving steel pertinax(die base). However, the AL-1100 does not require cooling when engraving fiber pertinax materials.