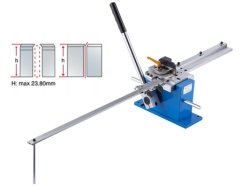

Pneumatic Nicking Grinder for Steel Rules of Die-Making Model: AL-213

If you have needs for nicking when making wood cutting dies, this pneumatic nicking grinder is one of the necessary tools.

- Pneumatic working mode, high efficiency, time-saving and labor-saving.

- Adopts well-known brand pneumatic motor core, CE certified for the EU market

- The pneumatic motor core is powerful, with a maximum speed of 35,000 RPM.

- Furthermore, the motor core vibrates very little, ensuring nicking precision.

- Comes with a high-precision measuring ruler, allowing you to easily control the distance between nicking dots.

- A transparent acrylic protective cover is installed at the front end of the nicking grinder to ensure safe use without obstructing the view.

- Datasheet

| Pneumatic nicking grinder | |

| Model | AL-213 |

| Supported Rule Thickness | 0.45mm(1pt)-0.71mm(2pt)-1.07mm(3pt) |

| Supported Rule Height | 8mm-32mm |

| Standard function | steel rule nicking |

| Working mode | Pneumatic driving |

| Machine Size | 360×80×190mm |

| Package Size | 520×230×205mm |

| Net Weight | 1.3KG |

| Gross Weight | 2KG |

| Gas pressure assistance | 0.6-0.8Mpa air pressure compressor |

Complete Guide

The role of nicking in cutting dies, why do we recommend you buy our pneumatic nicking grinder?

Do nicking on cutting die is a key process in die-making industry . On the one hand, it is mainly used to improve the separation effect of product materials and waste during the die-cutting job. On the other hand, it mainly helps to improve the durability of the dies.

- If you are not producing self waste cleaning dies, the product itself and the waste material will be completely separated after die-cutting. This will cause waste material to accumulate on the die cutting punching machine and affecting die-cutting speed. Bcuase this requires manual cleaning of the waste material, wasting time. Therefore, you can design nickings on the die. When the die cuts materials such as cardboard, adhesive labels, leather, etc., The nicking creates small notches on the blade of the die, forming predetermined tearing points.Then the waste material can then be manually separated,no breaks and burrs. Additionally, if this cutting die is used for cutting multi-layer materials, nicking can reduce material adhesion. For multi-layer composite materials or materials with adhesive backing, nicking prevents the cut edges from re-adhering due to stickiness, ensuring clean edges on the finished product.

- Nicking also plays a significant role in extending the service life of the dies. On one hand, nicking helps distribute stress. During continuous die cutting. the blade local area bears most of the punching pressure. Nicking can reduces blade wear by distributing stress, particularly effective when processing(punch die-cutting) high-hardness materials such as corrugated paper and PET materials.

On the other hand, Nicking can prevent blade chipping, safeguarding operator safety and preventing accidents. Blades without nicks are prone to chipping when cutting hard materials. So the nicking helps a lot,it absorb part of the impact force, reducing the risk of steel rule chipping.

What is the packing way of this pneumatic nicking grinder?

This tool is relatively small, so we generally use paper gift boxes for packaging and add shock-absorbing materials. If you purchase other equipment from us, we will place this gift box in plywood crates.

Send Your Inquiry Today