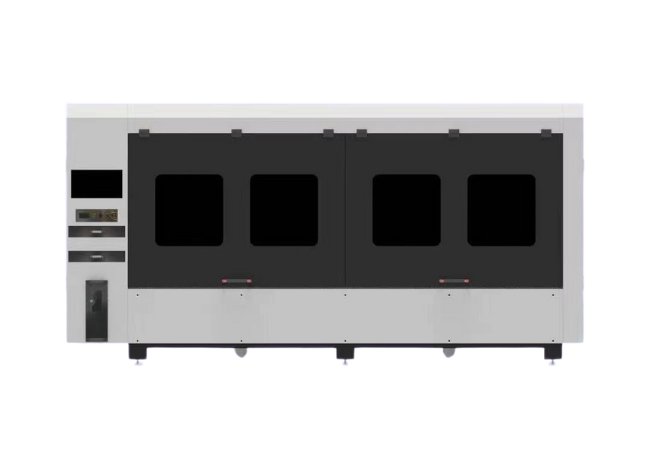

CNC Rotary Die Making Machine For Die-making Industry Model: AL-201

AOLANG LASER, as one of the most professional supplier of rotary die making equipment, provides you with the most stable and cutting efficient CNC rotary die making machines.

- The machine uses Japan Panasonic A6 series servo motors to ensure long-term stable operation.

- The physical transmission components use Taiwan HIWIN guide rails and PMI ball screws to ensure the machine’s cutting accuracy.

- Over 100 customers in the market have purchased and are using our machines.

- The machine base is formed with integrated welding process, then annealed at high temperature. And precision milled by a Japan OKUMA MCR – A5C precision milling machine.

- The machine uses an ultra-high-power machine core spindle with a maximum speed of up to 64,000 rpm, which is significantly higher than the machines from our competitors.

- Datasheet

| CNC Rotary Die Making Machine | |

| Machine Model | AL-8515R |

| The maximum cutting rotary board size | Diameter 150~850*3000mm |

| Repeated Positioning Accuracy | ±0.05mm |

| Cutting Speed | 0.6-1.0m/min |

| Cutting Thickness | 13-15mm birch/beech plywood |

| Transmission system | Ball Screw Drive with Servo Motors |

| Servo Motor | Japan Panasonic |

| Machine size | 4200mm×1100mm×2200mm(L×W×H) |

| Whole machine weight | 1900KGs |

| Power supply | 380V/50HZ 3500W |

| Repeated Positioning Accuracy | ±0.05mm |

| Spindle Rotate Speed | 64000 RPM |

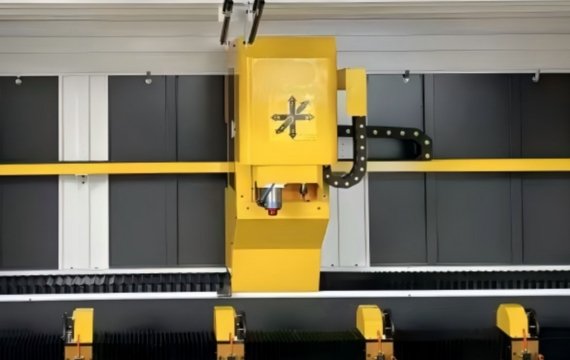

3-axis CNC Control System

A 3-axis control system specifically developed for the rotary die-making industry, capable of effectively cutting and forming rotary die boards. Fully automated control, simply import the drawings with one click and wait for the machine to complete the cutting and engraving.

The X-axis moves the main spindle left and right, with a standard travel distance of 3000mm, matching the standard length of rotary die boards.

The Y-axis serves as the rotation axis for the rotary die boards holding, enabling precise milling and rotational movement based on graphic positioning to complete the engraving and forming of steel rule installing seams.

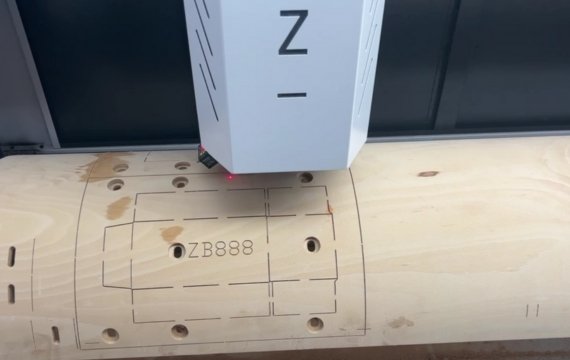

The Z-axis automatically adjusts the vertical height of the rotating spindle,different height of the tools will match the steel rules slot engraving,words you wanna engraving on the die boards, or the die board installation holes.

Ultra-high Speed Rotational Spindle

Industrial-grade powerful engraving spindle with a speed of up to 64,000 RPM, which can ensure the machine’s running, cutting and engraving speed.

In addition, the ultra-high speed spindle combined with a high-hardness engraving/cutting tools can effectively ensure the smoothness of the engraving edges and ensure no burrs. The high spindle power and speed also make the machine particularly adaptable, capable of engraving common rotary die board thicknesses of 13-15 mm.

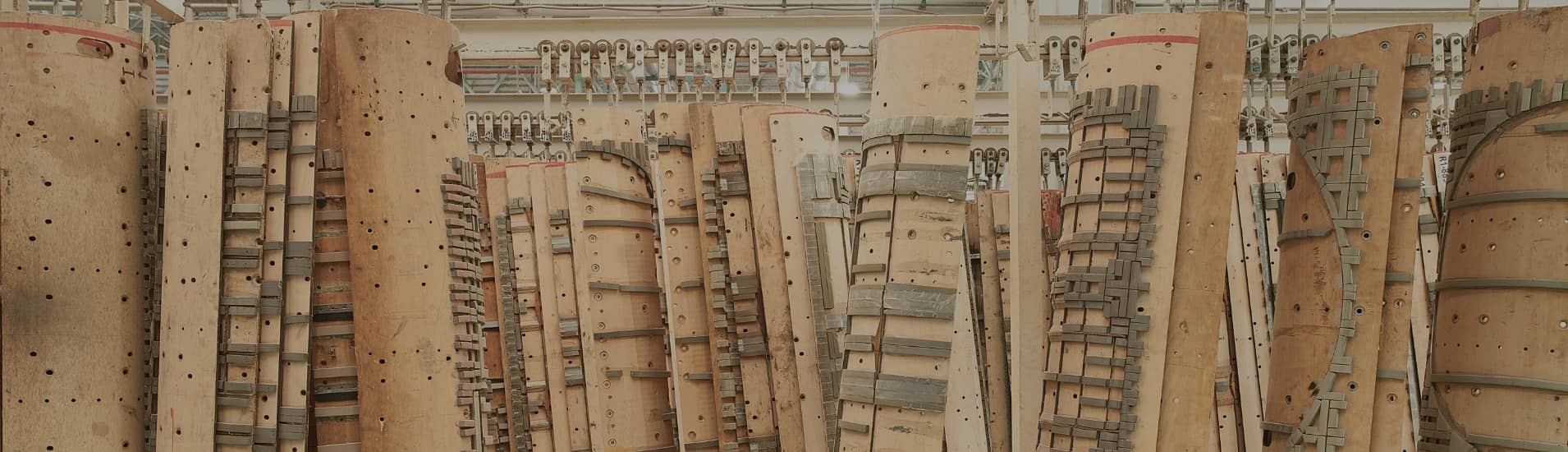

Specially Designed for Rotary Die-Making

This machine is essentially a CNC router. However, through a dedicated CNC control system, the Y-axis can be automatically rotated to complete the engraving of rotary steel rules installation kerf(slot) and installation positions of the rotary die board using for die-cutting installation.

Additionally, this machine features a specially designed rotating holding structure for rotary die boards. Before the machine begins engraving, you have to fix the rotary die board to the holding frame. The machine ‘s CNC control system and software will identify the optimal path and complete the cutting and engraving processes.

Rotary Die Making Related Equipment

Do you have laser rotary die cutting machine? What is the different of this CNC router with the laser die cutting machine?

We also have rotary die laser cutting machines. Eight years ago, we developed and produced our first rotary die laser cutting machine. However, the initial investment costs for laser cutting machines are relatively high, and their daily operating costs are also higher than those of CNC routers. Therefore, we developed a new CNC router cutting system to replace the laser cutting system. Currently, we more recommend the CNC rotary die making machine.

The main difference between the laser rotary die cutting machine and the CNC rotary die making machine is that laser machine uses thermal cutting, while the other employs physical engraving. CNC router system is a cold processing method.

- Laser machines require adjusting the focal length and laser spot size to adjust the width of the cut kerf to match your blade width. This requires a high level of experience and is quite difficult. However CNC routers can use a fixed tool diameter to match your blade width without any experience. They are very user-friendly for new machine operators.

- Laser machine has limited control over the processing depth of materials. Laser machine can generally only cut through materials or perform simple engraving on material surfaces. They cannot perform layered processing on materials. However, CNC rotary die making machines can not only cut through rotary die boards but also perform layered caving on them. For example, before die-making process, the rotary die needs to be secured to the die cutting machine with nuts, and a CNC router can perform this task effectively.

- The thickness processing capability of a laser rotary die cutter depends on its laser power. If you need to cut thicker materials, you will need a higher laser power. However, CNC routers have a very high adaptability to material thickness, generally capable of all the thicknesses rotary die board ranging from 13 to 20 mm.

- The daily operating costs of a CNC rotary die-making machine are lower, with its primary consumables being cutting tools. Although these tools may wear out and require replacement,but the costs are relatively low. And there are verious suppliers in the market, offering a wider range of options.

However, the laser source(fast-flow-axial) of the laser cutting machine requires a significant amount of inert gases, such as helium and CO2, for its daily operation. Additionally, its power consumption is higher than that of the CNC router. When considering the overall machine usage costs, the CNC router clearly offers a significant advantage.