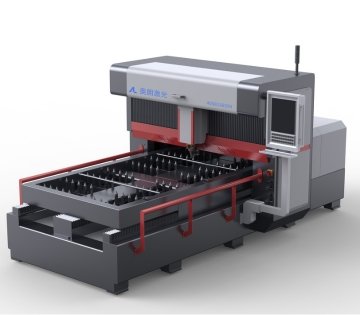

23.8mm Steel Rule Bending Machine

One of the necessary machines for wood board dies making. It can make you die-making work efficiency increase 5-10 times. Fully automatically bend and cut your steel rules.

- Common steel rule thickness 1pt 2pt 3pt matches

- Blade height range from 20 to 32mm

- Automatic bridging function,bridge width adjustable

- Automatic lipping function,lip size adjustable

High Precision Ball Screws

Aolang laser steel rule bending machine adopts double clamping system for blades feeding. Double ball screws with front and rear teeth work together. Also there are up and down double guide rail. TBI ball screws and HIWIN guide rail all are name brand with high precision guarantee. This precision mechanic feeding system to ensure the blade feeding accuracy of ± 0.02mm.

Servo Motor with Driver

Steel rule bending machine with servo motor systems for steel rules feeding and bending. The servo motors have a very good acceleration, which makes it possible to guarantee the speed of the steel rule feed and the bending speed of our machine. And it has a very low response delay, which can ensures the bending accuracy of the bending axes.

In addition, servo motors have a longer mechanical life, which is more than four times that of a normal stepper motor. Servo motor with 20 million cycles (IEC 60034 standard)

This is a good guarantee of the service life and low failure rate of our steel rule bending machine.

High Strength and Hardness Tools

The core functions of the Steel Rule Bending Machine, such as bending, bridging, and lipping , are all processed by the tools, so the tools for each function are wear parts. They need to be repaired or replaced periodically depending on the working hours.

Replacement of tools is part of the daily cost of the machine, but our machines are made of stronger and harder mold steel, which can significantly extends the service life of all the tools of each function.

- Data sheet

| Steel Rule Bending Machine | |

| Machine Model | AL-910C |

| Blade (thickness) | 0.45-0.71-1.07mm(1pt 2pt 3pt) |

| Blade (height) | 20-32mm(common size like 22.3,23.3,23.8mm) |

| Max Bending R | 100° |

| Min R in 90° | 1 |

| Min U shape bending size | 5mm |

| Minimum bending size on front/back | 1.5-2mm depends on the blade thickness |

| Standard functions | Cutting,bending,bridging,lipping |

| Blade feeding accuracy | ±0.02mm |

| Bending Flatness | 0.2/100mm |

| The way of cut | Multi-purpose scissors. It can cut front and back scraps |

| Gas supported | 0.6-0.8Mpa compressor air |

| Voltage and Frequency | AC 220V 50Hz |

| Gross Power | 2KW |

| Machine Size and Weight | 230CM*75CM*165CM 480KG |

| The best graphics formats | dxf.ai.dwg format |

The main features of the automatic steel rule bending machine AL-910C.

This machine is controlled by Aolang developed software, and the bridge width and double lipping are all set in the software. And then the machine automatically complete various processes such as bending, bridging, lipping, and cut the formed blade off.

In addition, the safety design is one of the most important features of this machine. The blade feeding system adopts a collision avoidance type to anti-jamming , which automatically stops the feeding when the blade is jammed due to some unknown reasons. As well as other work stations also adopt safety protection design. The bridge and lip cannot be punched through when the tools are seriously worn out, the servo motor will automatically reverse to return the blade and terminate the processing and wait for the manual repair before working again.

The 910C is an entry-level machine, and in addition to the standard bending, bridging, lipping, and cutting functions, we offer the optional Nicking function.

If more high-end functions like perforating,broaching,etc please check our AL-32CN PRO.

- Keep your workshop have enough space to put the machine ,the machine’s layout is 230CM*75CM*165CM(L*W*H)

- 220V 50Hz power supply

- 0.6-0.8 Mpa compressor

We can provide door to door shipping service to most of the countries.

You also can arrange the shipment by yourself. And the machine will be packed well by plywood crates as blow: