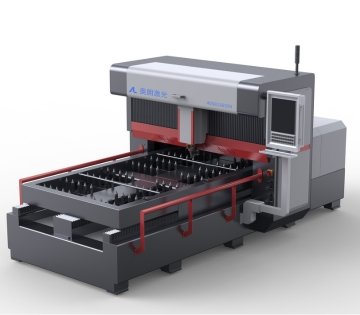

Automatic Steel Rule Die Bender

If wanna start a die-making business,the steel rule die bender is as important as a laser die cutting machine.

- Offering a wide range of functions to choose from,bridging,bending,cutting,nicking.

- All functions are modularized, so you can freely choose what functions you want.

- Fully automated one-click import of work jobs, automatic output, no need man guarding

- It comes with an error detection function, if error appears at any part of the machine software will automatically detect the alarm

All functions are modular design

As we all know, modular design modular design is good for our productivity. If you buy this steel rule die bender from us, we can deliver it to you faster than other competitors.

On the other hand, the modular design is more benefit to the machine users, because the modular design allows us to provide you with more customized functions. What features you want, just tell us.

And the modular design can make the maintenance of the machine become very easy. If any module is worn out, you only need to replace the module, simple and fast will not affect the use of other functions of the machine.

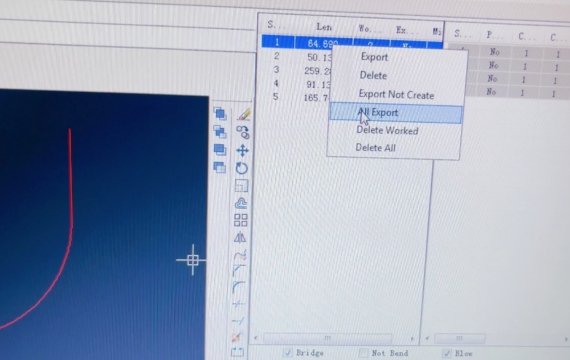

More automated and user-friendly software interface

We have upgraded and optimized our steel rule die bender’s control software. It support one-click working mode. For example if you need to do 10 jobs, you only need to import them all into the control software. Then click start and it will automatically bend and cut all the steel rule jobs you need.

Another great feature is that you don’t have to stand by and watch it work. It will work automatically after exporting, you just have to wait for it to finish its work and then collect the steel rules that have been formed. Then you can start to load the steel rule on the die board.

More stable bending and cutting way

Instead of the traditional bending rod and scissors separate structure,we adopted the integrated design of bending and cutting workstations in the AL-32CN model. The two functions are integrated into one rotary rod.

The benefits are two-fold. On one hand, the same workstation can increase the working speed of the machine by about 50%. On the other hand, by integrating the two functions, the machine uses less sensors and is less likely to get errors happening.

- Data sheet

| Steel rule die bender | |

| Machine Model | AL-32CN |

| Blade (thickness) | 0.45-0.71-1.05mm(1pt 2pt 3pt) |

| Blade (height) | 20-32mm(common size like 22.3,23.3,23.8mm) |

| Max Bending R | 100° |

| Min R in 90° | 1 |

| Min U shape bending size | 5mm |

| Minimum bending size on front/back | 1.5-2mm depends on the blade thickness |

| Standard functions | Cutting,bending,bridging,lipping(Nicking option) |

| Blade feeding accuracy | ±0.02mm |

| Bending Flatness | 0.2/100mm |

| The way of cut | Bending and Cutting at one Rotary Rod |

| Gas supported | 0.6-0.8Mpa compressor air |

| Voltage and Frequency | AC 220V 50Hz |

| Gross Power | 2KW |

| Machine Size and Weight | 230CM*75CM*165CM 480KG |

| The best graphics formats | dxf.ai.dwg format |

What is the different between AL-910CN and AL-32CN steel rule die bender?

Actually, both models’ basic functions are almost the same, all can do basic steel rule forming works, such as bending, bridging, cutting, lipping, nicking, and so on. But their cost is different,AL-910CN is entry-level more recommended for new business starter and you don’t have enough money for advanced version . And AL-32CN is an advanced version. It has a more advanced structure and faster working speed, as well as higher stability. More recommended for experienced die-maker or you have enough budget also recommended.

While it’s true that the AL-910CN is also a good entry-level choice. But if you can increase your budget, we’d recommend the AL-32CN. How this come?

- Modular design,it’s more easy to maintain and replace the wearing parts in your daily use.

- About 50% higher working efficiency will help you a lot when your business goes growing.

- AL-32CN straight cut is processed by molds(tool),the flatness of the edge is better than AL-91CN (scissor cutting).

1. Choose high precision HIWIN guide rail and TBI ball screw rod to ensure the precision of steel rule feeding.

2. Adopt high power servo motor and drive from Japan and pneumatic parts from SMC Japan.

There are three ways we can help you learn to use the machine,

- English manual .

- Operation video to guide you to use.

- Can send an engineer for the machine installation and training if needed.

Yes,Thanks to its modular structure,this machine can customize those advanced functions,hole punching,nicking,broaching all ok. Actually we have another advanced model AL-32CN PRO. More details,please click the link to check.